SWEPCO 702 Synthetic Universal AW Compressor Oil

Price on request

SKU: 1000970032- Description

- Additional information

- Key features

- Benefits

- Markets

- Applications

- Technical Data

Description

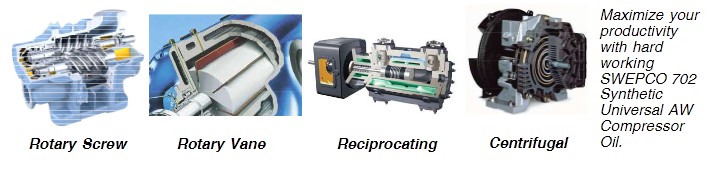

SWEPCO 702 Synthetic Universal AW Compressor Oil provides exceptional wear control in the most demanding compressor applications.

SWEPCO Syntheon™ synthetic base oil blends and patented LUBIUM® II oxidation and corrosion resistance chemistry extend lubricant life, keep the compressor clean, reduce wear, improve compressor efficiency, lower energy consumption, and increase productivity. Formulated for rotary, reciprocating, and centrifugal compressors.

Meets or exceeds the performance requirements of the following specifications:

- DIN 51506 (VBL, VCL, VDL)

- ISO/DP 6521 (DAA, DAB, DAH, DAG)

- USDA/NSF H2 & CFIA n1 (in closed systems)

Compatibility

Gases – Ammonia, nitrogen, hydrogen, helium, carbon monoxide, carbon dioxide (dry), ethylene, methane, propane, butane, propylene, butylene, natural gas, butadiene, furnace cracked gas, hydrogen sulfide (dry), synthesis gas, sulfur dioxide.

NOT recommended for breathing air or refrigerant gases.

Paint-Epoxy, Oilresistant Alkyd, Acryl Enamal Seals & Plastics-Acetal (Delrin), ABS, Phenolic, Polyamide-imide, Polyamide (Nylon), Polyester, Polyetherimide (Nylon), Polyimide, Polyfenyleen oxide, Polystyreen, Polysulfon, PTFE (Teflon), Terephthalate Elastomeren:, Fluoroelastomer (Viton), Nitrile (Buna N), Polyacrylate, TFE/P, Polyurethane.

NOT recommended for uncoated polycarbonate plastic, PVC plastic, or butyl, ethylene-propylene, or SBR rubber.

Switching to SWEPCO 702 Synthetic Universal AW Compressor Oil

Although compatible with mineral oils, PAOs, and some other synthetic oils, a thorough drain and cleaning is recommended before switching to SWEPCO 702. This will help reduce initial contamination and ensure optimal performance.

NOT compatible with polyalkylene glycol or silicone oils.

For optimal transition to SWEPCO 702, first use SWEPCO 728 In-Service System Cleaner or SWEPCO 729 Premium Flushing Oil.

When you want the best, choose SWEPCO 702.

Additional information

| Merk | SWEPCO |

|---|---|

| ISO | ISO 100, ISO 32, ISO 46, ISO 68 |

| SAE | |

| Shipping | Bin (930 kg./1020 liter), Drum (186 kg./208 liter), Keg (54 kg./60 liter), Pail (16 kg./19 liter) |

| Feature | Benefit |

| SyntheonTM Base Stock Blends |

|

| LUBIUM® II Antioxidant |

|

| Anti-Wear Additive |

|

| Rust & Corrosion Inhibitor |

|

| Anti-Foam Additive |

|

| Pour Point Depressant Additive |

|

| Energy Savings |

|

| Long service intervals |

|

| LabTecSM Fluid Analysis Program |

|

| Bottom Line Increased profitability through ... |

|

- Reliable, long service intervals in rotary, reciprocating, & centrifugal compressor applications

- Reliable service life up to 8,000 hours or more

- Actual superior anti-wear performance

- Syntheon™ synthetic base stock blends ensure exceptional performance at high temperatures

- Advanced LUBIUM® II antioxidant chemistry prevents carbon, varnish, and other performance-reducing deposits

- Unmatched protection against rust and corrosion

- Energy-efficient, improves compressor efficiency

- Specified for discharge temperatures up to 200°C

- Liquid to -40°F (-40°C) for cold weather applications

- UV-sensitive for quick leak detection and oil disposal quantity

- Agricultural

- Heavy Industry

- Industrial Equipment

- Air Compressors

- Reciprocating Compressors

- Lobe Compressors

- Screw Compressors

Would you like more information about this product? Contact us at info@stratson.nl.

We will send you via email, for example:

Case studies

Technical data sheets

Material Safety Data Sheets

Let us know via email what kind of information you would like to receive.

Or download the TDS or MSDS below tab Technical Data.