SWEPCO 103 Moly High Impact Plus Grease

Price on request

SKU: 1005160001- Description

- Additional information

- Key features

- Benefits

- Markets

- Applications

- Technical Data

Description

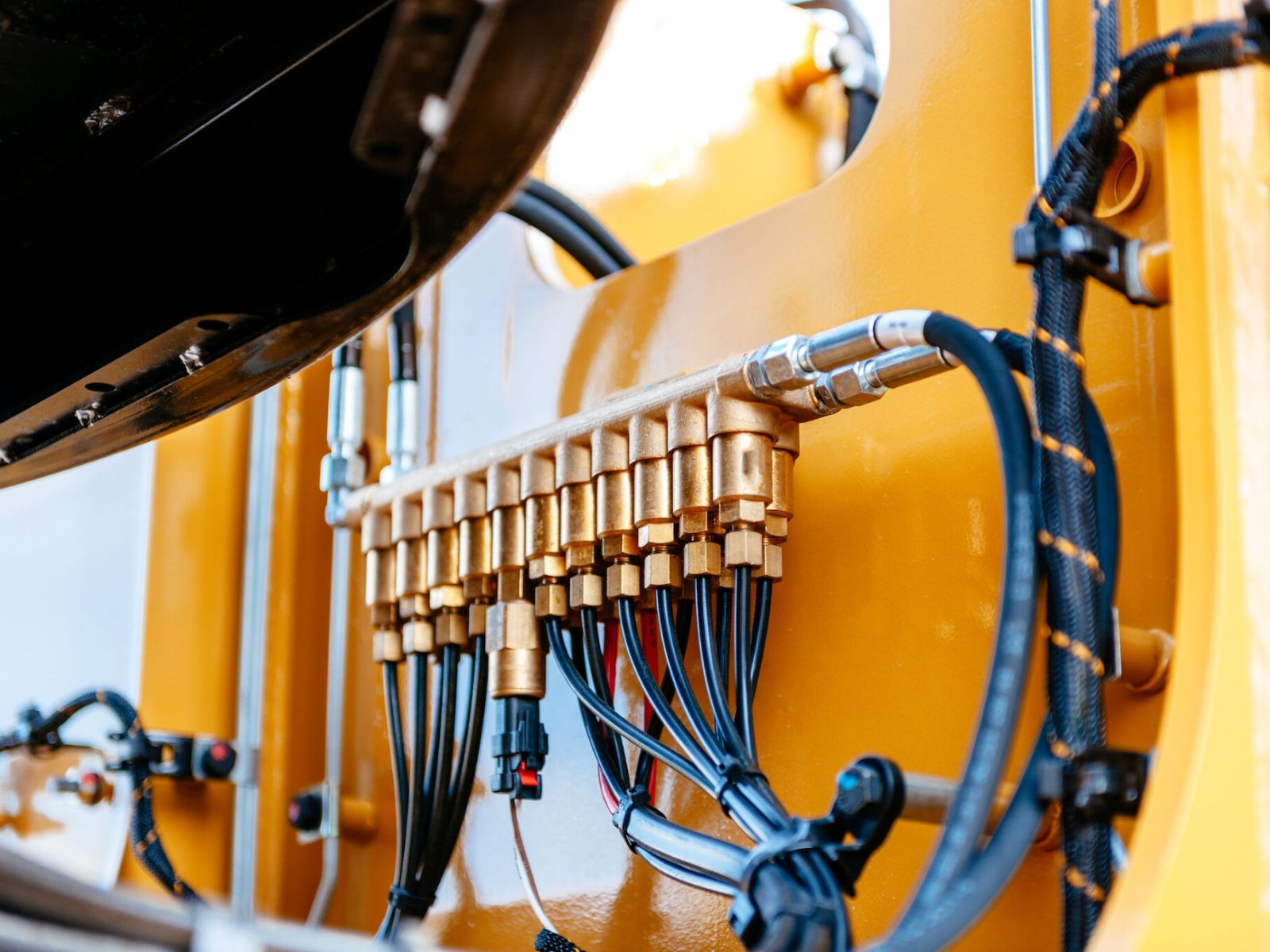

Until now, equipment owners who wanted the high shock, water, and corrosion resistance of a barium grease had to give it up when choosing the cost-saving, anti-friction features of a “moly” enhanced grease. But… no longer! SWEPCO 103 Moly High Impact Plus Grease is the answer.

Now, both the superior performance of barium grease and the unique anti-friction and anti-wear properties of “powdered moly” are available in a single premium quality multi-purpose grease. This product is also suitable for use in (battery) grease guns… SWEPCO 103. This unique grease has superior extreme load and anti-wear properties, in addition to all the normal performance benefits of SWEPCO 105 HI Plus Grease.

SWEPCO 103 Moly High Impact Plus Grease reduces friction and heat.

One of the key reasons for the superiority of SWEPCO 103 is the addition of powdered molybdenum disulfide. Powdered molybdenum is not a conventional extreme pressure additive that only works at elevated temperatures caused by heavy operational conditions. Powdered molybdenum is a truly unique anti-friction compound that continuously works to reduce friction, heat, and wear.

Moly works by coating metal surfaces with a microscopically thin anti-friction film. It has a high affinity for metal and also one of the lowest friction coefficients known.

This highly effective molybdenum film provides an extremely durable second lubricating layer that reduces friction and resistance, far below the levels encountered with conventional greases.

The result is a significant reduction in heat and heat-related failures. Equipment runs cooler with increased load-bearing capacity, operational efficiency, and component lifespan in conditions where regular greases would fail.

Water treatment plants and other corrosive environments |

Heavy shock |

Extreme pressure |

Exposure to water |

Additional information

| Merk | SWEPCO |

|---|---|

| NLGI | |

| Shipping | Doos met 10 patronen, Doos met 30 patronen, Drum (186 kg./208 liter), Pail (16 kg./19 liter), Vaatje (54 kg./61 liter) |

- High film strength, tough, fibrous consistency

- High resistance to fresh and saltwater, dust, grit, and acids

- High temperature performance up to 190°C (375°F)

- Oxidation protection with rust and corrosion inhibitors

- Contains SWEPCO's patented anti-friction and anti-wear additive, LUBIUM®

- High alkaline reserve

- Molybdenum disulfide

- Excellent performance under the most adverse conditions

- Fibrous structure builds a dust barrier

- Helps neutralize acidic mixtures and other corrosive substances

- Reduces grease consumption

- Improves energy efficiency and extends equipment lifespan

- Anti-friction/anti-wear protection from Moly Powder

- Industrial Equipment

- Heavy Industry

- Road & Water Construction

- Mining

- Pins and Bushings

- Chemical Equipment

- WWTP Aerators, Pumps, Valves

Would you like more information about this product? Contact us at info@stratson.nl.

We will send you, for example:

Case studies

Technical datasheets &

Material Safety Data Sheets

Let us know by email what information you would like to receive.

Or download the TDS of MSDS under the Technical Data tab.

You may also like…

You may be interested in…

-

Alemite emmerpomp 7149-4

Price on request -

Alemite ALE-500 Schaarvetspuit

Price on request